- Charts & Publications

-

Marine Industry

-

Recreational

-

Land Market

-

Harbour equipments

- Proteção Covid-19

- About Us

- Novidades

- Marcas

- Contacts

- Serviços

- Articles

- Home /

- Land Market /

- Sonic cleaning /

- Pulsator

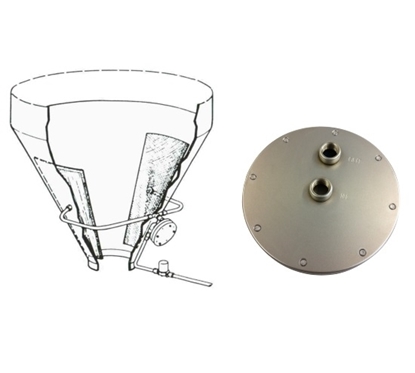

Pulsator

![]()

The Pulsator System is using low frequency air pulses to fluidise the material stored in any silo. This discharge system has been developed for efficient loosening of material and to avoid bridging in any type of silo. In this case the activator operates by means of rapid compressed air impulses from a wholly pneumatic pulsator.

For smaller silos a steel pipe can be sufficient to distribute the pulsating air.

For larger size silos, there is a need to use two or more panel activators so that the air pulses can be distributed over a larger surface. The air that is blown in is thus finely distributed so that it forms a slip surface over the panel activator surface. The pulsating air is distributed in between each particle and displaces them easily. This combination results in especially efficient emptying, the mass of material is set in uniform movement, and it shows a minimal tendency to segregate. The system is highly flexible, as the size, shape and location of panel activators can be adapted to all different designs of the silo – i.e. metal or concrete silos with straight or curved sides. This type of silo discharge will not create any mechanical demolition of the silo walls. The activation of the pulsator can be made automatic by means of a solenoid valve or manually.

A mobile Pulsator-Lance can be used for discharge from truck-containers or in other temporary problem areas.

Pulsator

- Praceta Augusto Dias Silva, 94 2B 2785-521 Sao Domingos de Rana

- info@jgarraio.pt

- Tel.: +351 213 473 0810

As fotos apresentadas podem não corresponder as configurações descritas.

Preços e especificações sujeitos a alteração sem aviso prévio.

A J. Garraio declina qualquer responsabilidade por eventuais erros publicados no site.

Desenvolvido pela Agência PRIMEWAY - Plataformas Digitais • Design • Marketing Digital